Fargol Pooya Tejarat specializes in the production of various PET preforms in different neck sizes and weights, tailored for use in the beverage, food, pharmaceutical, cosmetic, and hygiene industries. Our products are fully compliant with health standards, and the company is also equipped to produce both transparent and colored preforms for diverse applications.

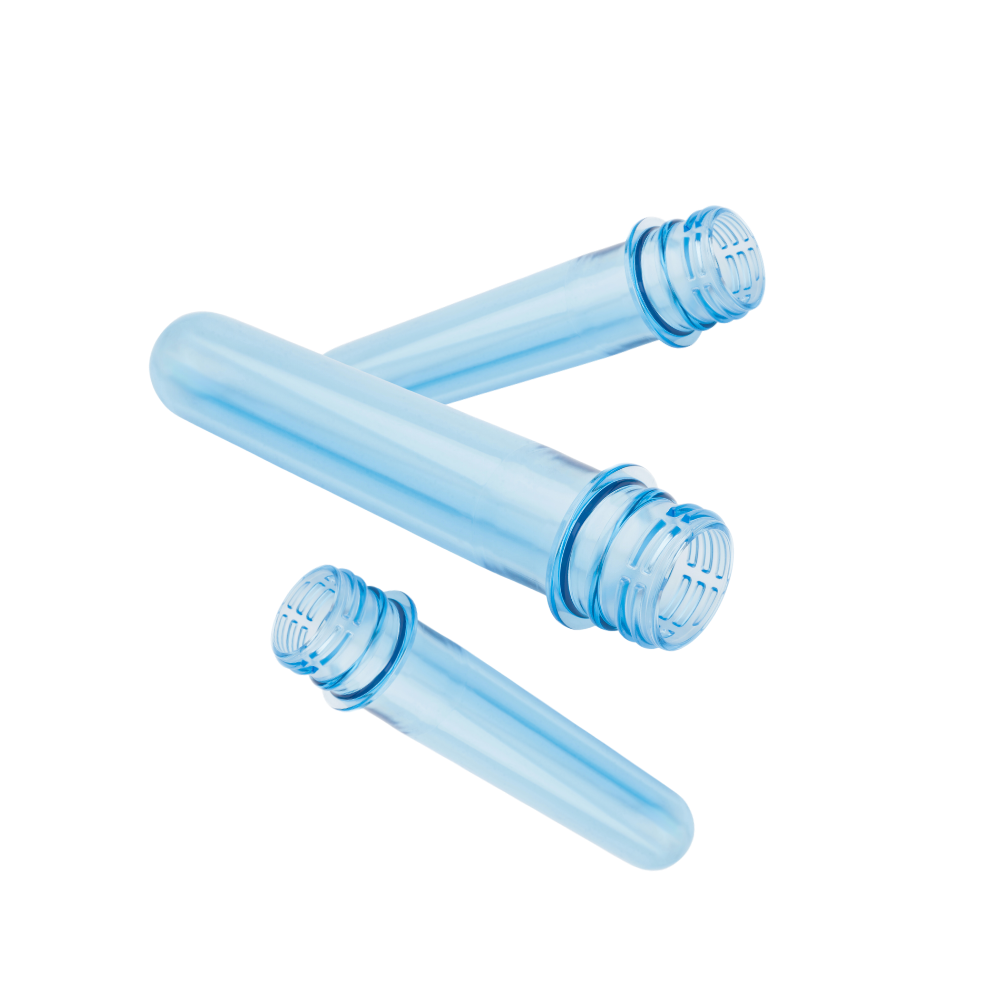

In the plastics industry, “Preform” refers to semi-finished components typically made from polyethylene terephthalate (PET) and used as the initial stage in the production of plastic bottles.

Production Process:

Plastic Injection:

First, PET plastic granules are fed into the injection molding machine, where they are melted at high temperatures.

The molten plastic is then injected into a preform mold to create an initial shape resembling a tube or bulb.

Cooling and Preparation:

After injection, the preform is removed from the mold and cooled. These preforms usually resemble an unfinished bottle, complete with a neck but with a short and compact body.

Blowing and Final Shaping:

Once cooled, the preform undergoes a process called blow molding. In this step, the preform is reheated to soften and then placed into the final bottle mold. Air is blown inside, transforming the preform into a fully formed bottle.

Advantages and Applications:

Cost Reduction in Production and Transportation: Since preforms take up less space compared to fully finished bottles, they are easier and more cost-effective to transport and store. They are then transformed into the final bottle at the production or packaging site.

Design Flexibility: Preforms can be produced in various sizes and shapes, making them suitable for manufacturing different types of bottles, including those for soda, mineral water, and detergents.

Key Points:

Preforms are typically manufactured with high precision to ensure the quality and performance of the final bottle.

The color and transparency of preforms can vary depending on the customer’s needs and the final product requirements.

Fargol Pooya Tejarat is a premier producer of high-quality plastic preforms, utilizing cutting-edge technology and superior raw materials to serve the packaging industry with a diverse product range. Our dedication to excellence ensures preforms characterized by exceptional strength, crystal-clear transparency, and optimal moldability, enabling the production of plastic bottles in a variety of sizes and shapes.

Choosing Fargol Pooya Tejarat means opting for quality, precision, and innovation. We are committed to meeting your needs with reliability and expertise, delivering solutions that set the benchmark in plastic preform manufacturing.

Production of Beverage Bottles:

Preforms are widely used to produce plastic bottles for beverages such as mineral water, soda, juice, and dairy products. These bottles, with their high strength and clarity, are ideal for preserving the flavor and freshness of the products.

Packaging for Detergents:

Plastic preforms are used to manufacture bottles for detergents such as shampoo, dishwashing liquid, laundry detergent, and other industrial cleaning products. These bottles offer good resistance to chemicals.

Pharmaceutical Industry:

Preforms are utilized in the packaging of pharmaceutical products such as disinfectant solutions, dietary supplements, and hygiene products. Bottles made from preforms are sanitary, lightweight, and durable.

Food Packaging:

Certain food products like sauces, cooking oils, vinegar, and similar items are also packaged in bottles made from preforms. This type of packaging helps preserve the quality and extends the shelf life of food products.

Cosmetic and Personal Care Products:

Plastic preforms are used in the production of bottles for personal care and cosmetic products such as creams, lotions, and sprays.

Chemical and Agricultural Industries:

Preforms are used to produce durable packaging for fertilizers, pesticides, and industrial chemicals. These packages are highly resistant and prevent leakage and degradation of the contents.

Custom and Specialized Packaging:

Companies can customize preforms based on their specific needs, including bottle size, volume, and shape, and use them for packaging a wide variety of products.

Plastic preforms, due to their lightweight, strength, and recyclability, are an excellent choice for various packaging industries.